Services

What We Offer

As the preferred metal services center in the Middle East, we are equipped to carry out complex metal forming processes to design and manufacture any architectural product or system to match our customer's requirements.

Our group prides itself in housing some of the world’s most advanced and large format machinery to carry out coil processing to small parts CNC milling. Our service portfolio also includes various in-house surface treatment solutions that include Electropolishing, Pickling, Passivation, Anodizing, Blasting and Painting.

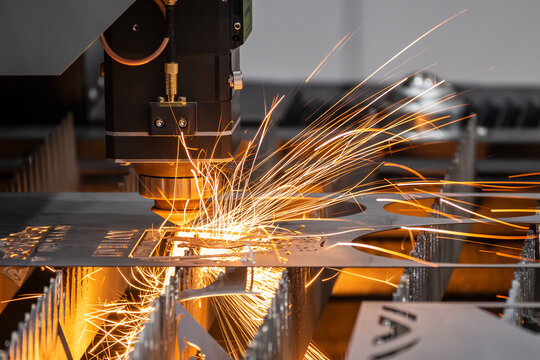

LASER CUTTING

Laser cutting is a technology that uses a laser to cut

materials, and is typically used for industrial manufacturing

applications : a laser is a device that generates an intense

beam of coherent monochromatic light used in drilling and

cutting, alignment and guidance

SHEET BENDING

We house the largest plate/ sheet bending machine in the

Middle East. It is Robust, Accurate, Speedy, Flexible and

easy operating.

ROLLING

In metalworking, rolling is a metal forming process in

which metal stock is passed through one or more pairs

of rolls to reduce the thickness and to make the thickness

uniform. The concept is similar to the rolling of dough. A

plate rolling machine is a machine that will roll different

kinds of metal sheets into a round or conical shape. It can

be also called a “roll bending machine”, “plate bending

machine” or “rolling machine”.

V GROOVING

Bending metal using a V-Grooving machine allows it to be folded to a tight radius, or sharp corner. This enables folded metal to mimic solid bar material at around a tenth of the cost and also avoids wastage. V-Grooved profiles look just like solid bar material but are light in weight and easier to transport and install. V-Grooving and folding creates minimum waste and is on average a tenth of the cost of working with solid bar metals. V-Grooving can be created not just in one shape of V. Wider V, semi-circular and square grooving is also possible allowing for a range of design variations.

DRILLING

Many applications, usually involving either mounting parts

or routing wiring and other materials, require holes to be

drilled or punched into sheet metal. As with any other

typical fabrication task, there isn’t always a right or wrong

way to do the job. But, sometimes there is a better way.

We, with over 20 years of experience as the most preferred

service center in UAE pride in having the best machinery

and most seasoned technicians to carry out metal sheet/

plate drilling for varied applications.

SS PIPE POLISHING

Stainless steel Pipe polishing is a loose abrasive process, used to generate surfaces with very high tolerances in geometry, surface integrity, and roughness characteristics. This smoothness is obtained by rubbing the surface with the polishing particles with a rotating disc. Our state-of-the-art machinery polishes stainless steel tubes and pipes in Mirror and Brush finish.

CNC SPINNING LATHE

This machine will facilitate services for below stated metals

& dimensions;

Type of Metals: Stainless Steel, Carbon Steel, Aluminium,

Copper

Max Thickness – Stainless Steel: 0.5 – 1.0mm

Max Thickness – Aluminum & Copper: 0.5 – 2.0mm

Max. Thickness – Carbon Steel: 0.5 – 2.0mm

Max Product Diameter: 1000mm

Max Product Length: 450mm

Spinning Wheels: 4+1

CNC LATHE

A Computer Numerical Control CNC- Lathe machine that turns material around a central spindle and stationary cutting tool. It is a metal fabrication method where written code controls & amp; determines everything from spindle RPM to and movement of each cutting tool. It rotates a workpiece on a spindle to perform various operations such as turning, drilling,

facing, boring, threading, etc. to produce a symmetrical object.

Material: Stainless Steel, Carbon Steel

Capabilities

Max Dia. 65mm | Max Length 230mm

CNC LATHE – DAEWOO – PUMA 230MS

SINGLE TURRET, DOUBLE CHUCK

Max Dia. 40mm | Max Length 450mm

CNC LATHE – TORNADO A50

SINGLE TURRET, SINGLE CHUCK

Max Dia. 40mm | Max Length 100mm.